MIURA began with the

Z boiler

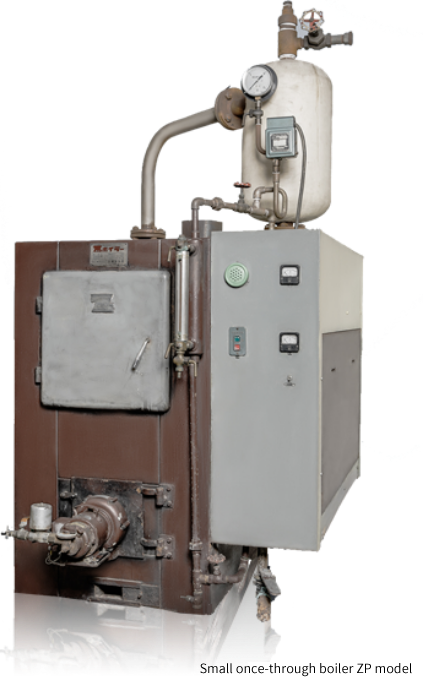

Tamotsu Miura began developing boilers in 1956 as a new business, completing the Z boiler, a small once-through boiler ZP model, in 1959. The concept behind this name was that since Z is the last letter in the alphabet, it would signify that "Nothing can come after this."

Its small size, compact form, and low price meant that any one could operate the ZP model with ease, winning it explosive popularity from small and medium-sized businesses as a boiler built with foresight and creativity.

Over the half-century since then, MIURA has repeatedly taken on new challenges as we innovate in the boiler industry.

Here we would like to tell you about the boilers that gave rise to MIURA.

What is a boiler?

A boiler is a machine that heats water in a closed vessel,

creating steam and hot water.

The first industrial revolution brings

with it the birth of the boiler

Boilers trace their origins back to the first industrial revolution in the 18th century.

Work that had previously been done by hand, such as cotton weaving, was mechanized.

Furthermore, steam was used to power these machines, helping to increase productivity.

Steam engines developed from boilers were put to use in transportation, allowing the efficient transport of people and goods over long distances.

Although steam engines gave way to the internal combustion engine, boilers remain in use as the primary source of heat in a variety of areas.

Small once-through boilers

become the standard for industrial boilers

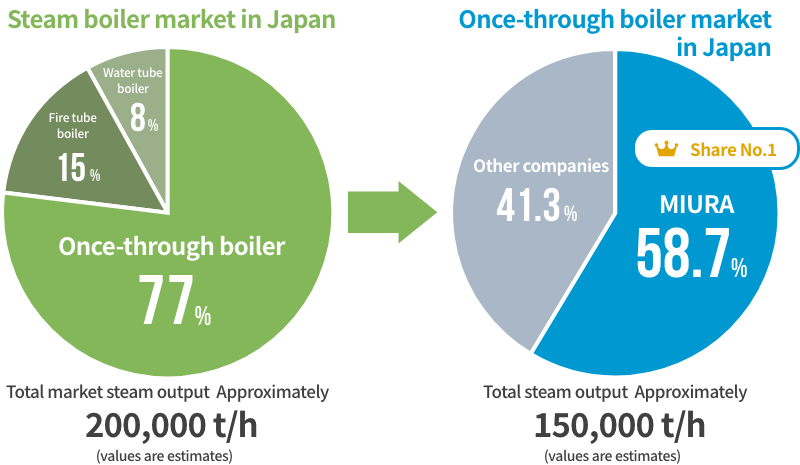

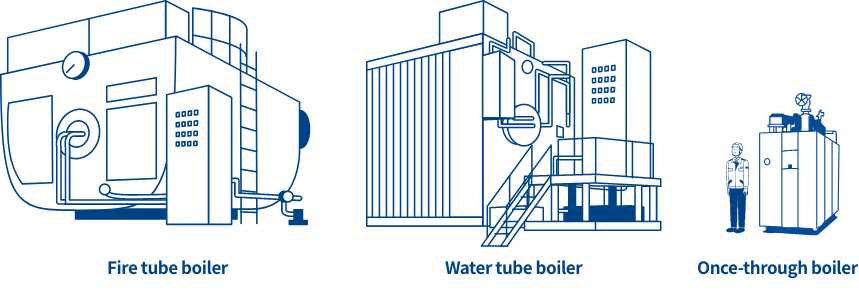

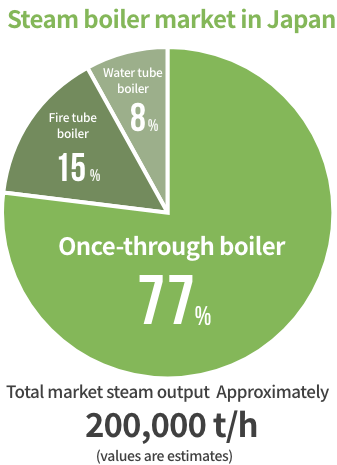

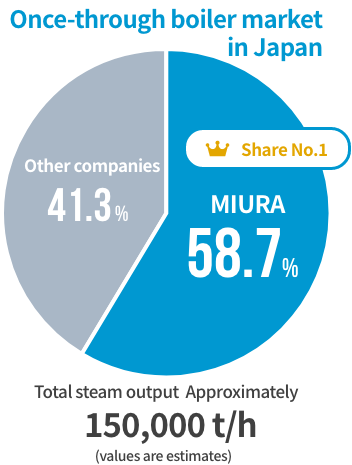

With the exception of the large-capacity boilers used in the power generation business, fire tube boilers and water tube boilers were the mainstream in the industrial boiler market. However the arrival of the once-through boiler in 1959 saw approximately 80% of the market transition to these new boilers over a period of approximately half a century.

Currently, approximately 60% of the once-through boilers used in Japan are MIURA boilers.

Share of the domestic industry

*Excluding those used for power generation (As at March 2019, according to MIURA research)

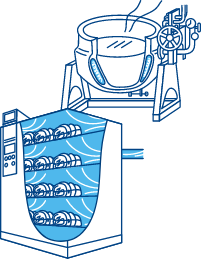

What is steam used for?

Steam stores the heat added to water to turn it into steam,

which can then be used as heat energy for a variety

of applications.

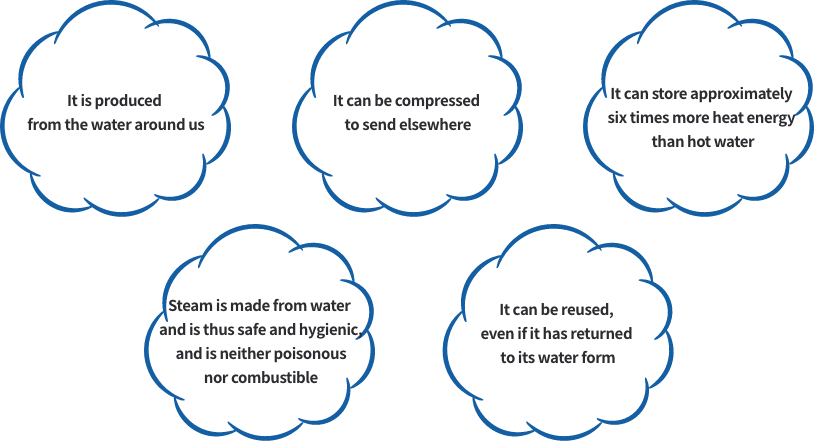

What are the merits of steam?

Where is steam used?

MIURA innovation

MIURA led the industry with a range of different innovations.

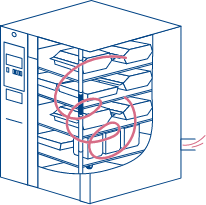

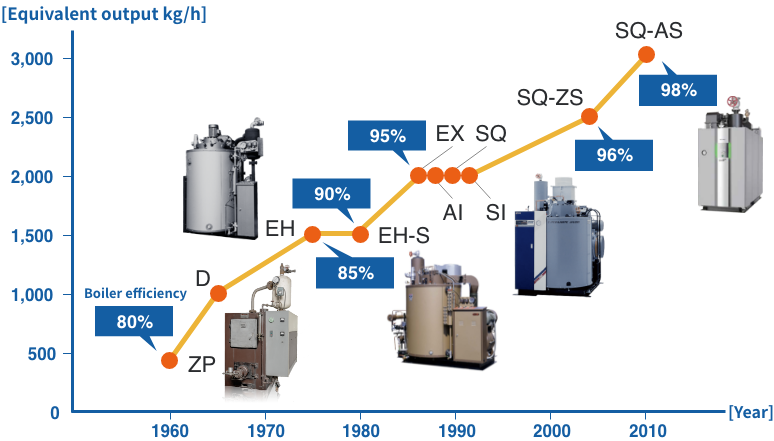

Pursuing boiler performance

Small once-through boilers are legally required to have a pressure of 10 kgf/cm or less and a heating surface area of 10 m² or less. MIURA has continued with initiatives to improve boiler efficiency in order to create energy within these stipulations without waste.

From the first ZP model, which had a boiler efficiency of approximately 80%, models now have evolved to have a boiler efficiency of 98%, achieving a system efficiency of 100% in some operating conditions thanks to the ability to recover even the latent heat present in exhaust gas.

Moreover, progress has been made with lowering NOx in products out of concern for the environment, helping to address environmental issues in Japan and around the world.

Progress with once-through boilers

Maintenance that preserves a high level

of boiler performance

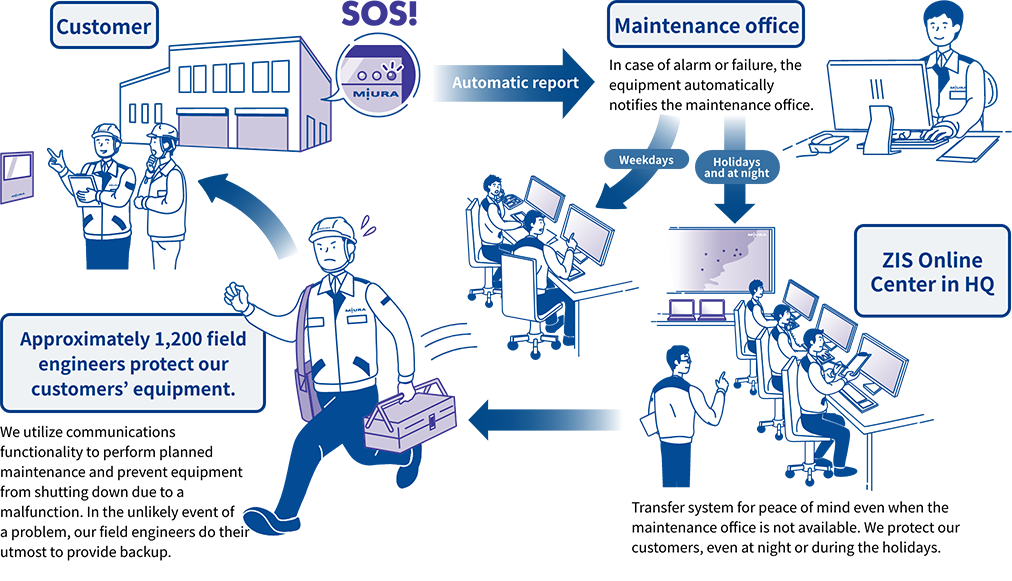

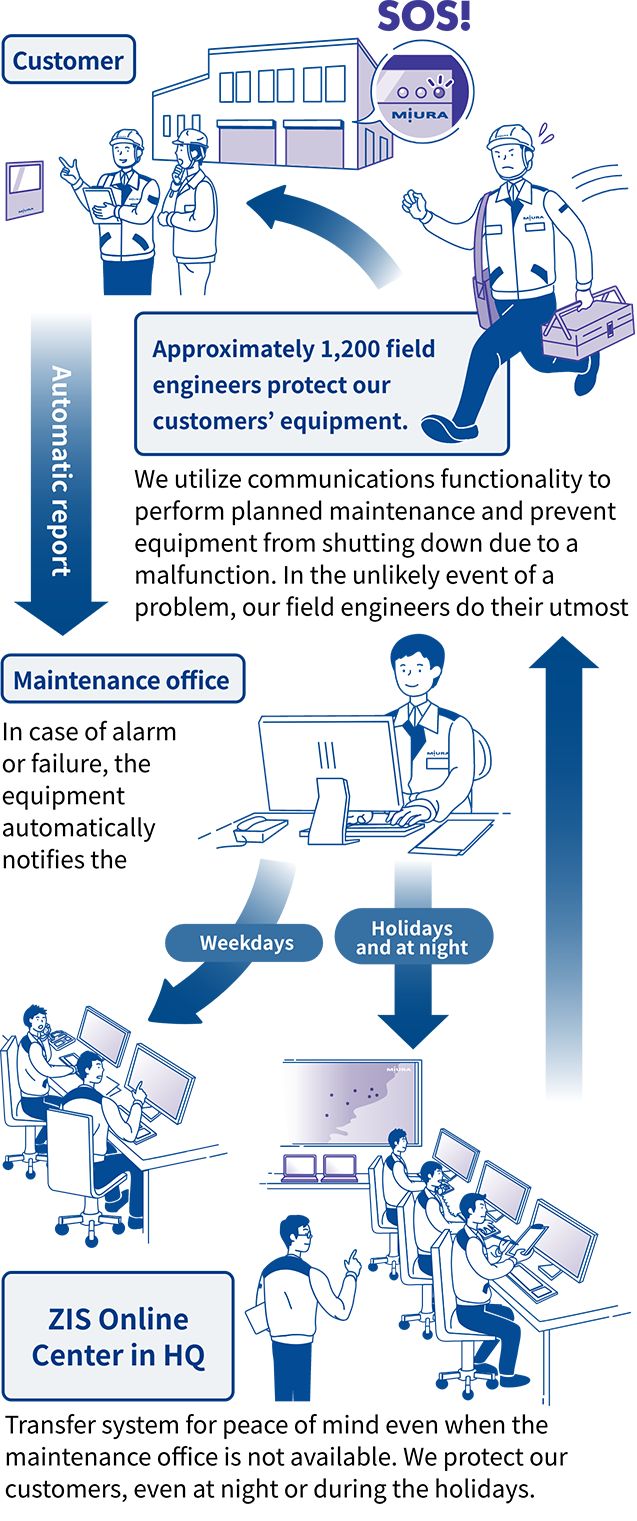

High-performance boilers are precision equipment. They require maintenance in order for customers to use them for extended periods with peace of mind. MIURA performs unique manufacturer maintenance, preventing trouble in advance while allowing a high standard of performance to be maintained.

Additionally, we link MIURA products through communication to offer reliable online maintenance 24 hours a day, 365 days a year.

ZM contracts (paid maintenance and inspection) start

ZMP contract system begins

AI-type steam boilers are launched, and ZIS online maintenance begins

ZM contracts (paid maintenance and inspection) start

ZMP contract system begins

AI-type steam boilers are launched, and ZIS online maintenance begins

Reliable online maintenance 24 hours a day, 365 days a year

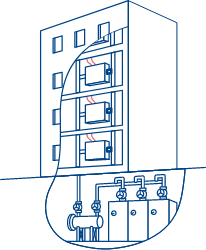

Development of MI (Multiple Installation) system

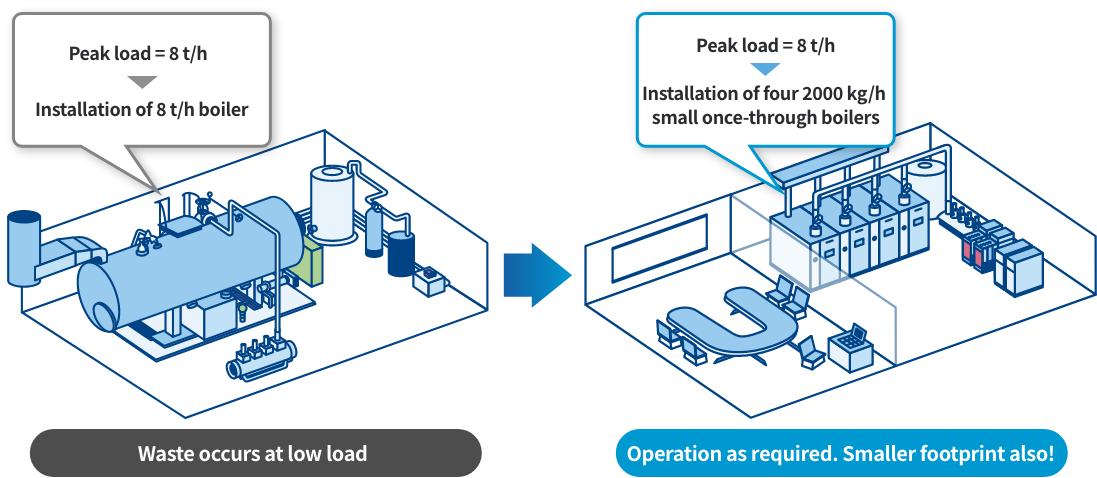

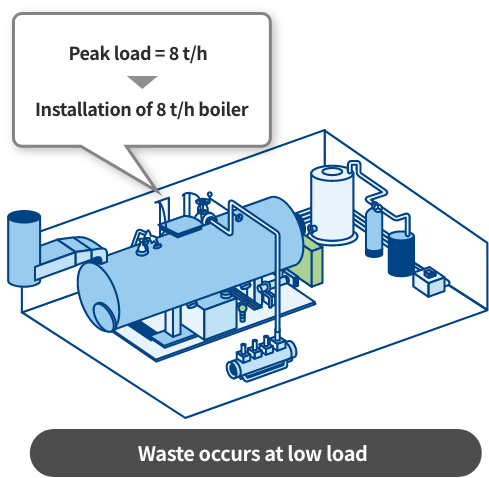

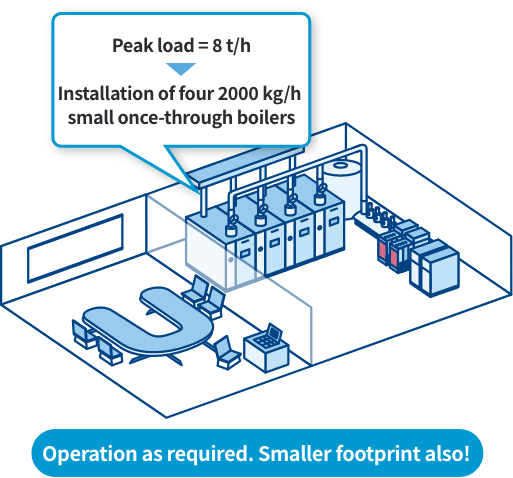

You could say that it was MI system® that converted the industrial boiler market to small once-through boilers. Although capital investment requires boiler capacity at peak load, boilers in factories do not operate constantly at full capacity.

For example, for a steam capacity at peak load of 8 t/h, by having MI systems and installing four 2000 kg/h small once-through boilers instead of the previous 8 t/h boiler, companies are able to operating with just the boilers they need to provide the required capacity.

MI system is making a significant contribution to conserving energy.

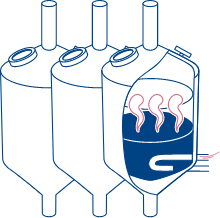

Obtaining next-generation energy

In addition to taking innovation of the boiler room, by reviewing energy loss through the entire factory or facility with a total solution, we can achieve further efficiencies that could not be achieved with boilers alone.

Thoroughly reviewing the flash steam, waste hot water, exhaust gas, and boiler water treatment found in many factories and using these effectively helps to reduce CO2 emissions.

Hydrogen has gained attention as a clean energy source with zero CO2 emissions, and we are working on the development of hydrogen-fueled boilers. In January 2017 we commercialized the first product in Japan capable of running solely on hydrogen*.

*By MIURA's own research

heat pump

hydrogen-fired boiler