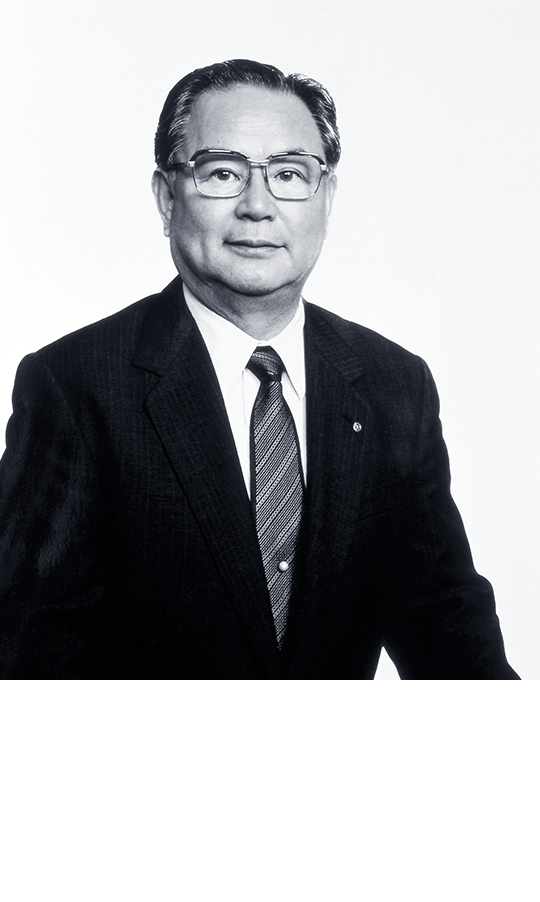

Father and son taking on business challenges as a pair

Founding of Miura Seisakusho

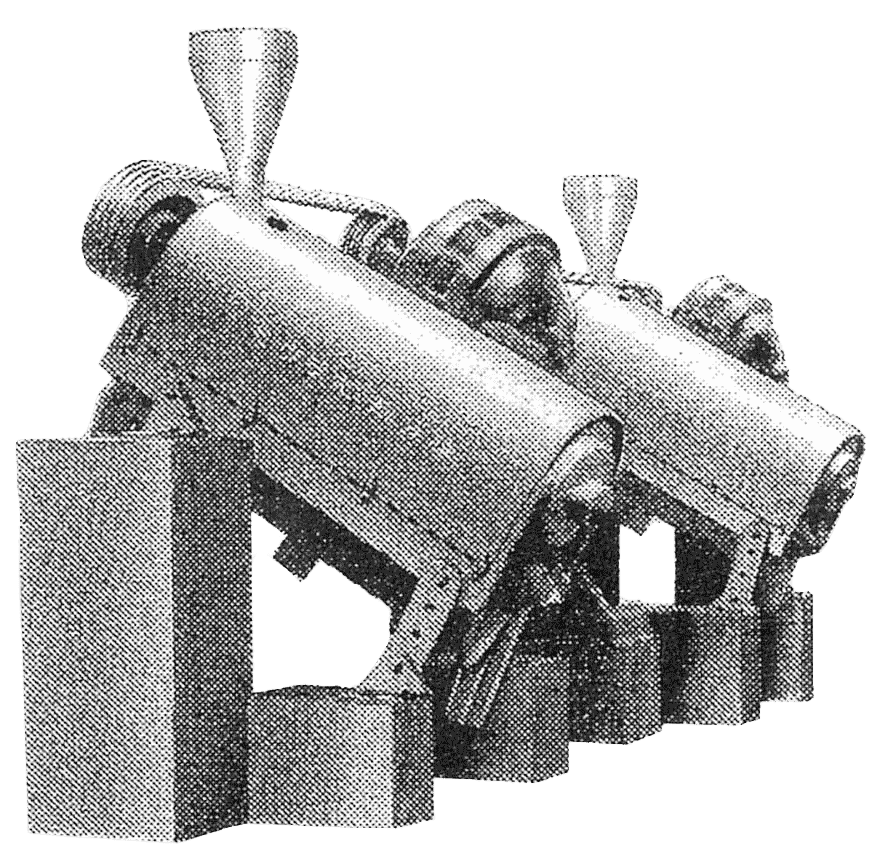

Father of company founder Tamotsu Miura foresaw the potential demand for agricultural machinery for use in an area where manual labor was the norm. He founded the Miura Seisakusho in Matsuyama, Ehime, and began to manufacture and sell machines for polishing barley and rice.

Photo: MIURA inclined barley mill

Starting with

5 employees

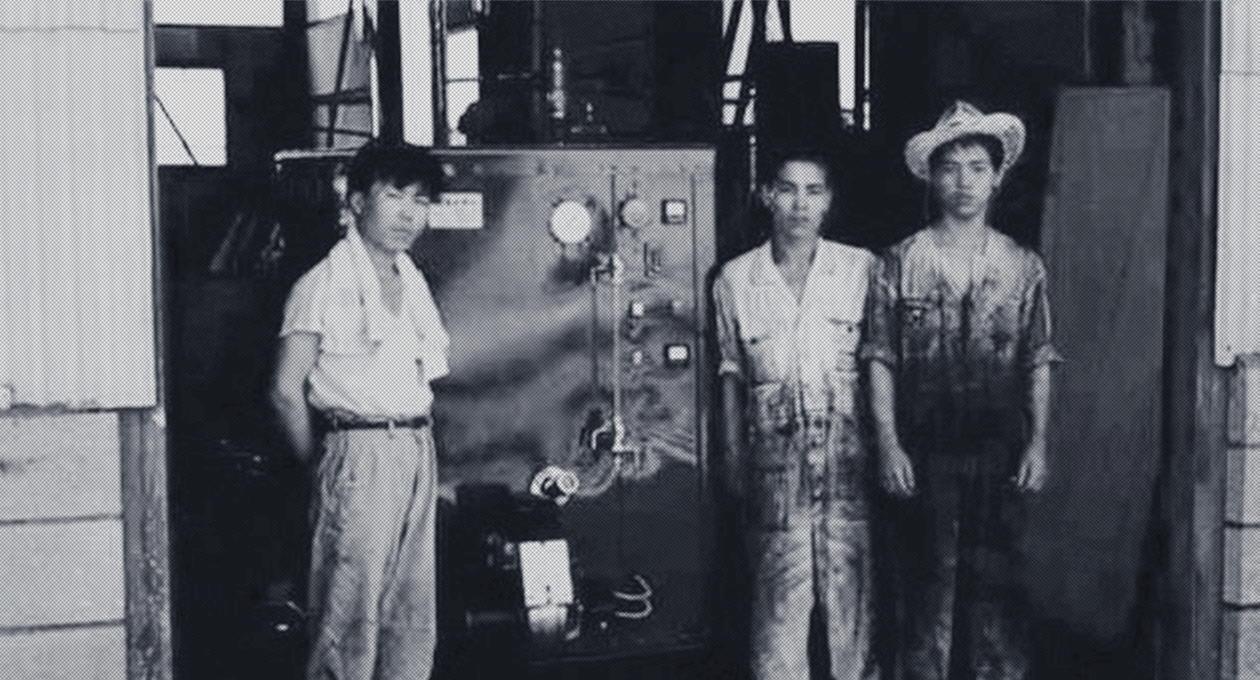

Incorporation of MIURA SEISAKUSHO CO., LTD.

As the economy expanded, MIURA foresaw that demand for boilers as a fundamental piece of machinery would grow and took the step of making the company's own model. Boilers with a multiplicity of uses had varied applications, and they became a driving force behind the development of MIURA.

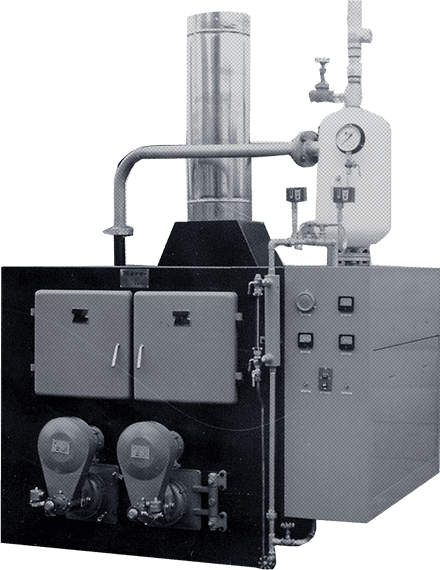

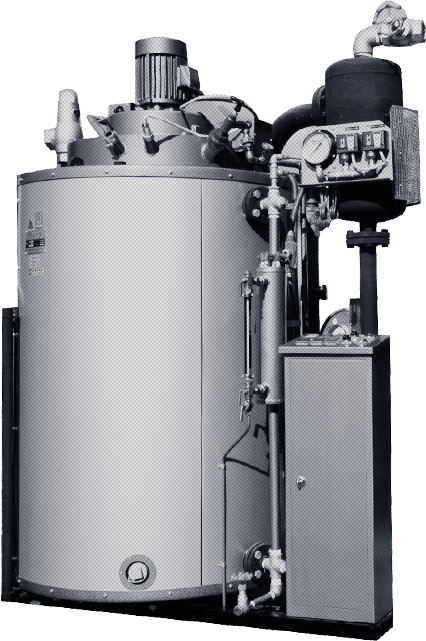

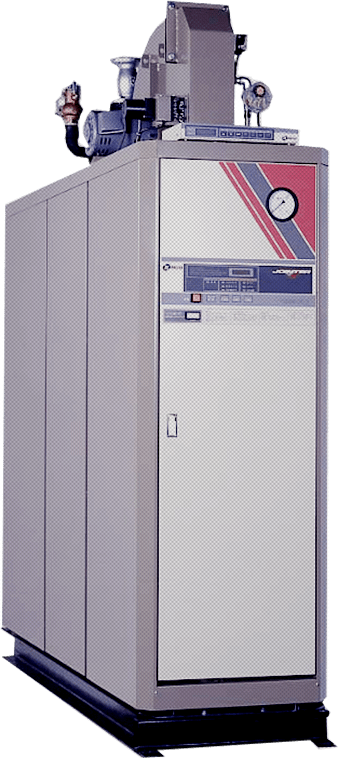

Sales start of small once-through steam boilers

With the easing in boiler safety regulations, MIURA developed a small once-through boiler utilizing it's own pressure vessel construction. Manufacturing began in earnest.

Photo: ZP-model

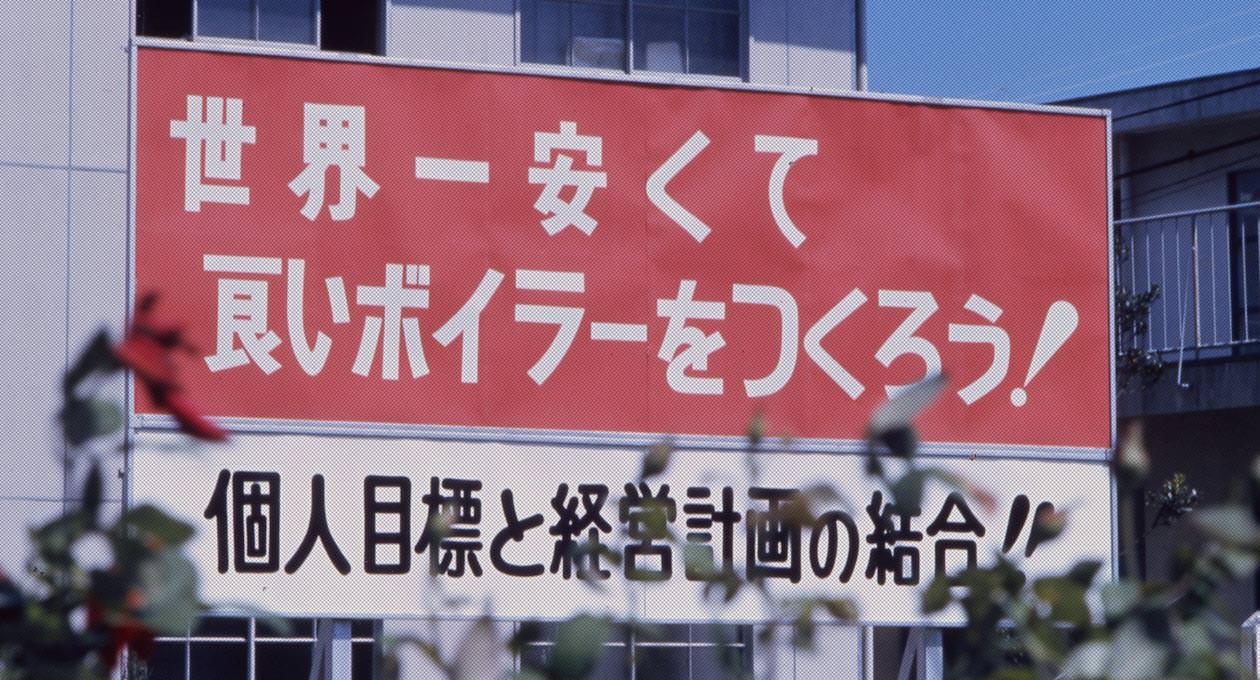

We will make the boiler of the world's best price and quality ever!

Launch of the ZM contract system

(a fee-based maintenance and inspection system)

We changed the name of after-sale service to "maintenance", providing it for a fee.

Photo: Brochure introducing the ZM inspection system

Launch of the ZMP contract system

MIURA launched the ZMP contract system (three-year fee-based maintenance and management service) that also covers parts and repair costs, starting the unique maintenance and inspection business.

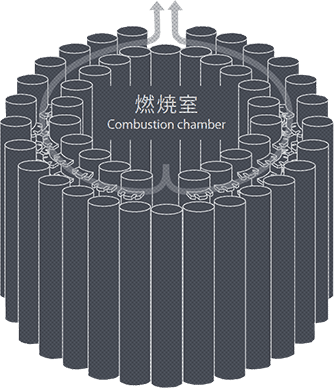

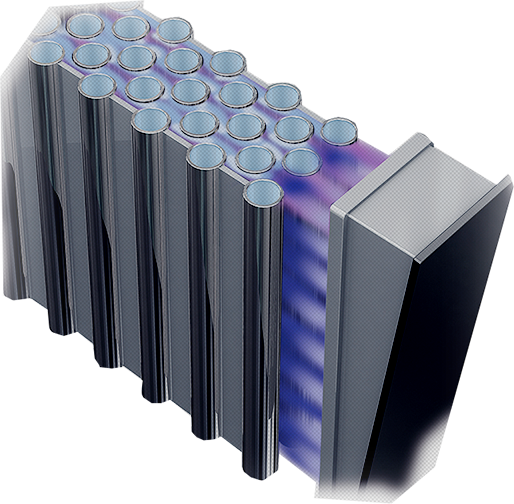

Debut of the ω (Omega) flow

pressure vessel (EH-model).

MIURA developed the landmark ω (Omega) flow pressure vessel that is the basis for the multi-tube once-through steam boiler.

Photo: EH-500

Commercialization of the MI (Multiple Installation) system, revolutionizing the boiler industry

MIURA was able to create the MI (Multiple Installation) system for combining multiple small once-through steam boilers thanks to the use of an automated multiple-unit controller. This made it possible to handle a large steam load.

Setting forth to cultivate foreign markets

MIURA established its International Department, laying the foundations for proactively opening new markets and globalizing operations.

Technoservices

opening the door to the future

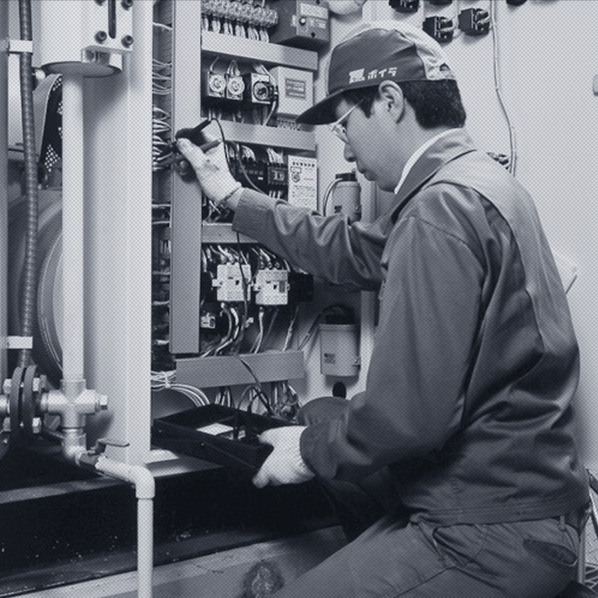

Establishment of "Technoservices"

MIURA established it's own services, guided by the twin policies of having "technology useful to our customers" and being "people true to ourselves who our customers love and rely on."

Sales start of AI-model steam boilers,

followed by launch of the ZIS online maintenance system

MIURA began sales of the AI-model steam boilers that can convey information about their current operation status and about whether any malfunctions may be imminent. Furthermore, the following year MIURA established the industry's first maintenance system that connects boilers and MIURA offices by telephone line to operate 24 hours a day 365 days a year.

Photo: AI-2000

Debut of the environment-friendly

"non-furnace" pressure vessel boiler

MIURA developed the "non-furnace" pressure vessel with no combustion chamber and launched the low NOx, space-saving, high efficiency steam boiler SQ-model.

Photo: SQ-1200

Offering new solutions for energy and water

Sales start of residential water softeners

MIURA set to work at expanding its business into even more diverse directions, and started to develop the HO-model residential water softeners. Around this time, MIURA entered the household appliance field in earnest as the soft water life promotion business.

Photo: Nantarō

Seeking to be the best partner for energy, water, and environmental needs through the evolution of Technoservices

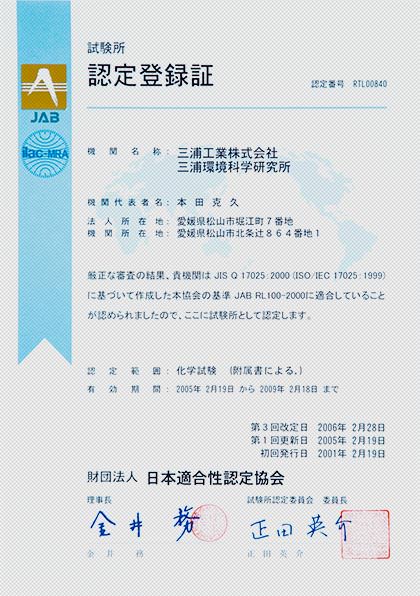

Technological capacity to conduct dioxins analysis on par with world's best

MIURA received the first ISO/IEC 17025 certification in Japan as the laboratory in the chemical testing field (environmental analysis). MIURA's self-developed dioxins analysis technology was certified with JIS, becoming the industry standard and contributing toward improving analysis precision while reducing workloads.

Photo: ISO/IEC 17025 certificate

Industry's first low NOx levels of less than 25 ppm achieved with SQ-model steam boilers

MIURA sought to offer more environmentally aware products and services by introducing the industry's first low NOx steam boilers and the zero-chemical technology for making minimal use of chemicals in treating boiler water.

Photo: SQ-2000ZS

Launch of Global Online Maintenance (GOM) system in North America and Asia

The ZIS online maintenance system developed in Japan has also been rolled out overseas. The system was introduced at the North American and Asian markets.

The Best Partner of Energy, Water and Environment

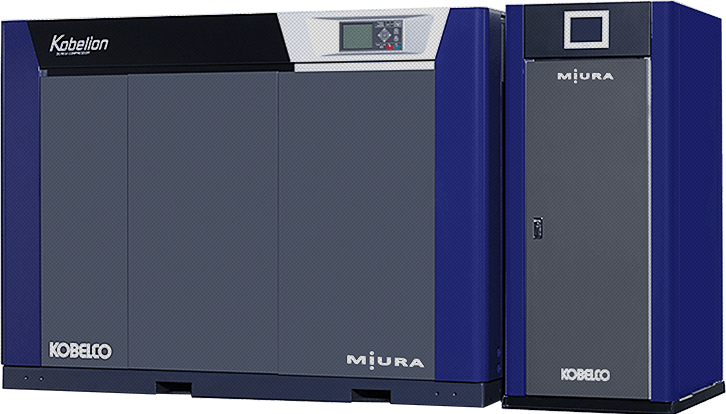

Offering total solutions and providing comprehensive one-stop maintenance

MIURA worked to improve energy efficiency in every corner of customers' factories, with every unit of the MIURA Group united to deliver comprehensive one-stop maintenance. MIURA also directed energies toward the new business of recovering and putting to use unused heat such as through its SD-model steam-driven air compressors.

Photo: SD-1310CO

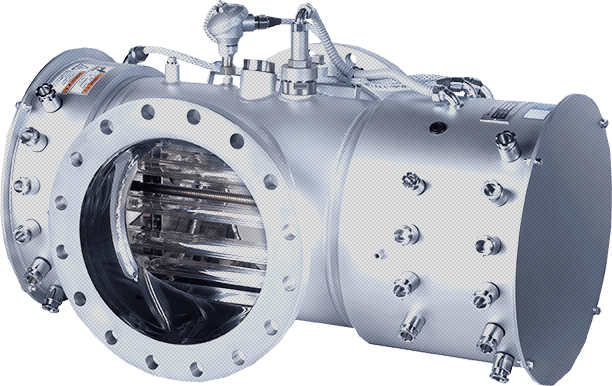

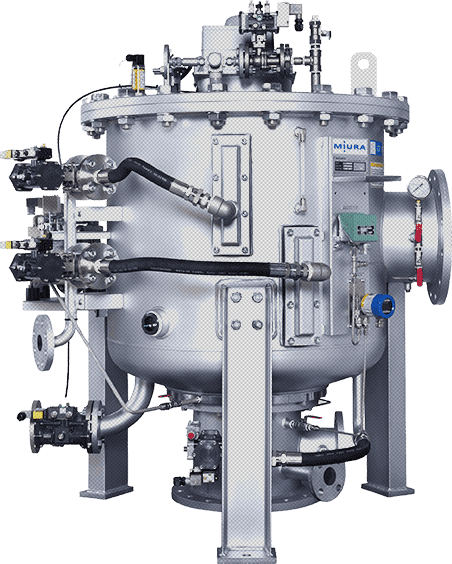

Development of the ballast water management system to protect the ecosystems of the world's oceans

MIURA began sales of the HK-model ballast water management system, which cleanses ship ballast water and protects the ecosystems of the world's oceans.

Photo01: Ballast water management system: UV reactor

Photo02: Ballast water management system: Filter unit