Marine composite boiler GK

- GK-1428~2730

- Actual Evaporation:

Oil Fired Side: 500~1,500kg/h

Exh.Gas Side: 400~1,400kg/h

Main Features

-

High efficiency

On the burner side, 80% and more boiler efficiency is secured by the newly developed boiler proper, and gas flow speedup promotes the heating improvement. Soot blower is arranged on the Exh. gas side water tubes, and then good efficiency operation is realized

-

Compact size

The newly developed boiler proper shortened the boiler height. The boiler weight also was reduced.

-

Long life

The water tube structure with reasonable strength brings about long life.

-

Wide stream chamber

The wide steam space brings about the strong structure against the load change.

-

Sequencer control

The sequencer control brings about the compact control box, and raises the reliance.

-

Sequencer control

The Exh. gas outlet on the burner side is designed to face sideways and it improves the maintenance. Moreover, in case of troubles, the boiler operation is possible by plugging and the water tubes can be replaced easily.

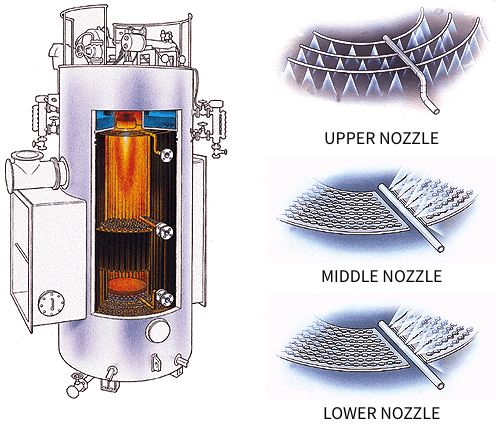

Structure of Ablecompo

We adopt the simple vertical water tube type. On M/E Exh. gas side, the water tubes are arranged around the upper and lower drum in consideration of good heat efficiency. Exh. gas from the flue duct flows right and left side separately (W FLOW) and the heat exchange is completed. After that, it becomes the low temp. Exh. gas and flows out. On the burner side, heat absorption is acted on water tubes with w FLOW structure, after combustion and heat radiation heating in the combustion chamber consisted of the most inside water tubes.

Air Soot Blower

High press. Air soot blower proposal.

High press. Air soot blower proposal.

The fixed branch soot blower is arranged on Upper and Lower tube plate, and high press. air from them blows into the water tube shaft to remove the soot effectively. High press. air from lower also blows up the soot deposited on the plate to the flue duct. On the center of water tube, the fixed or turning air soot blower is arranged to remove the soot around the center. Prevention of sulphur corrosion and effective soot removal are realized, because water is never used for the soot blower.

For product-related inquiries